Overview

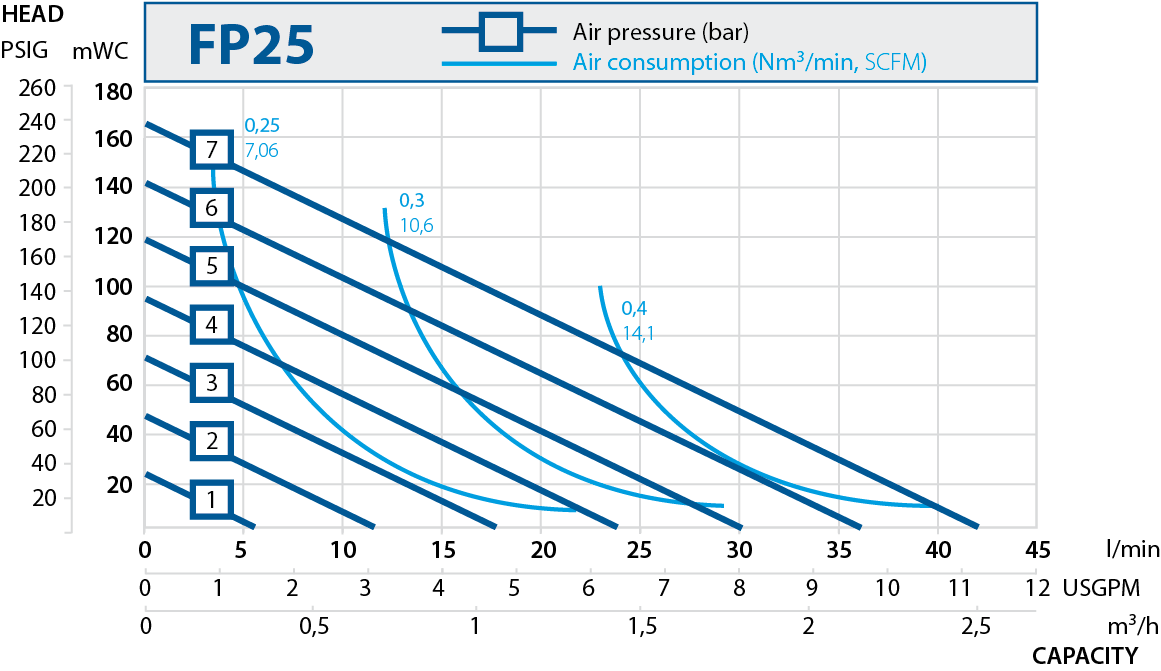

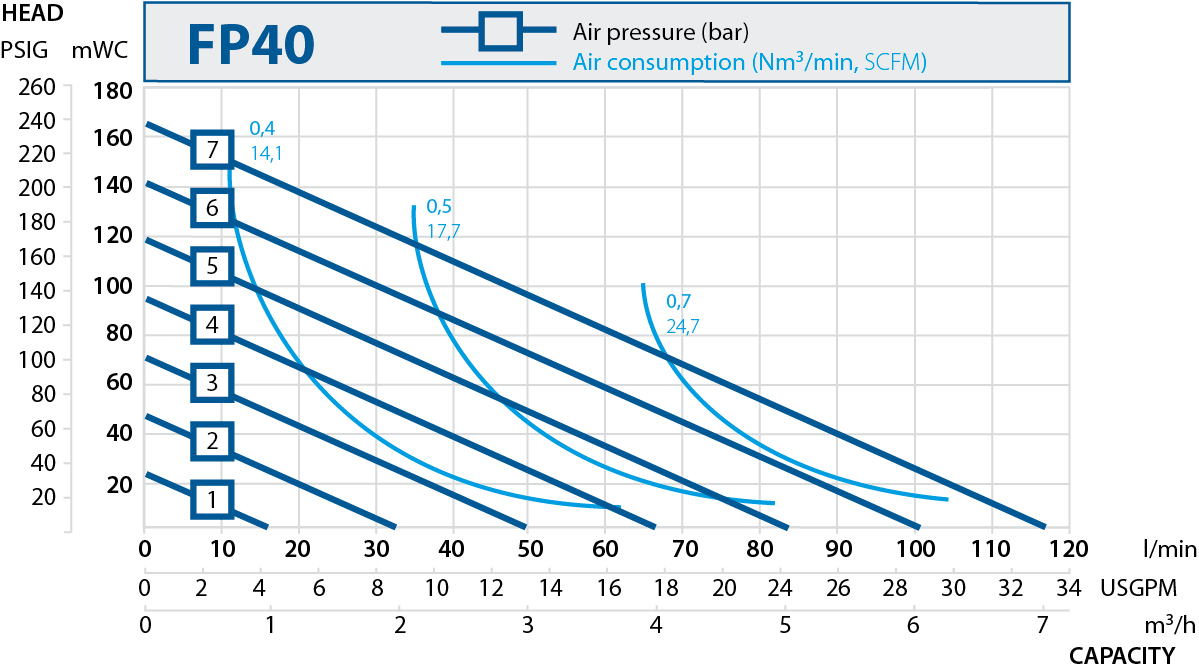

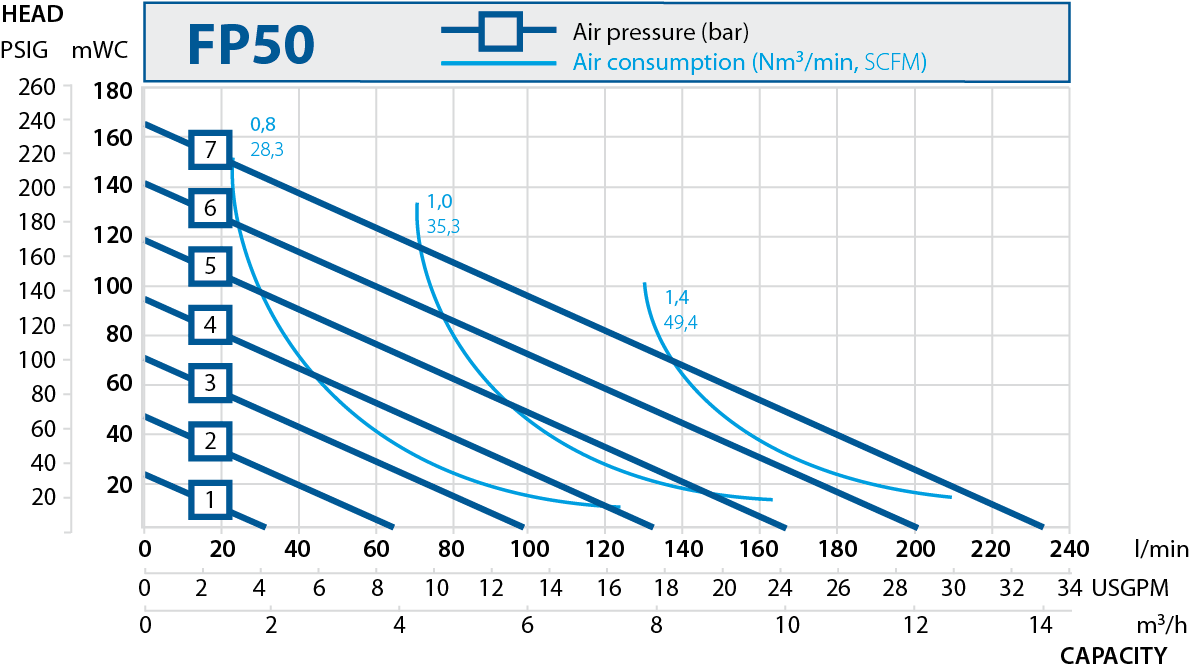

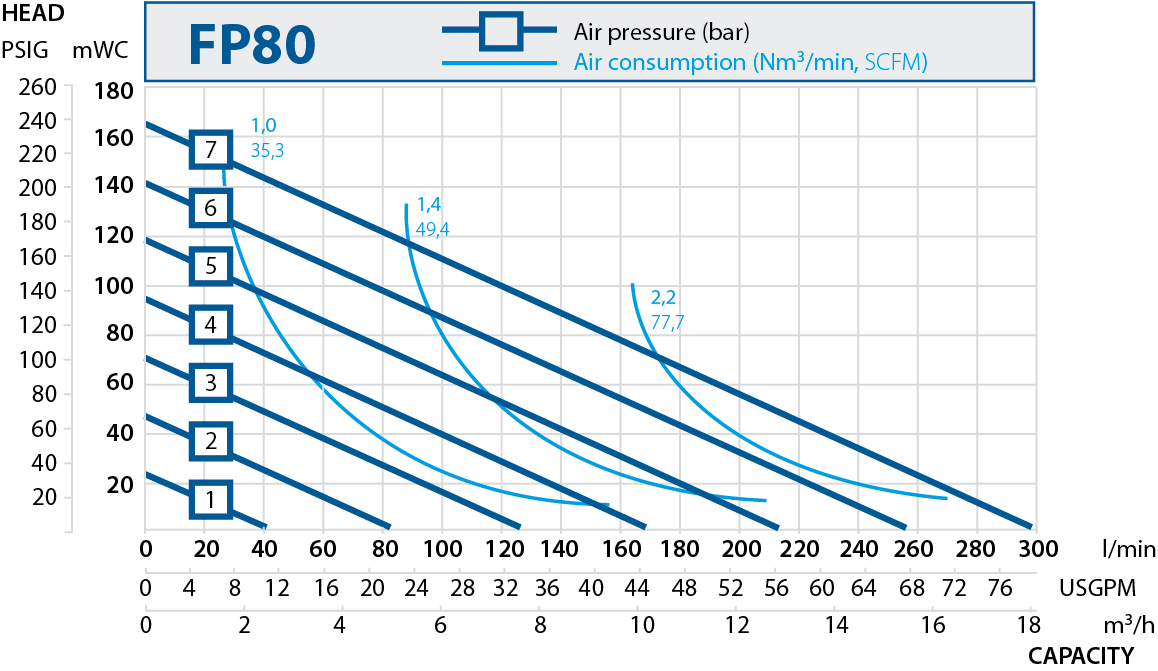

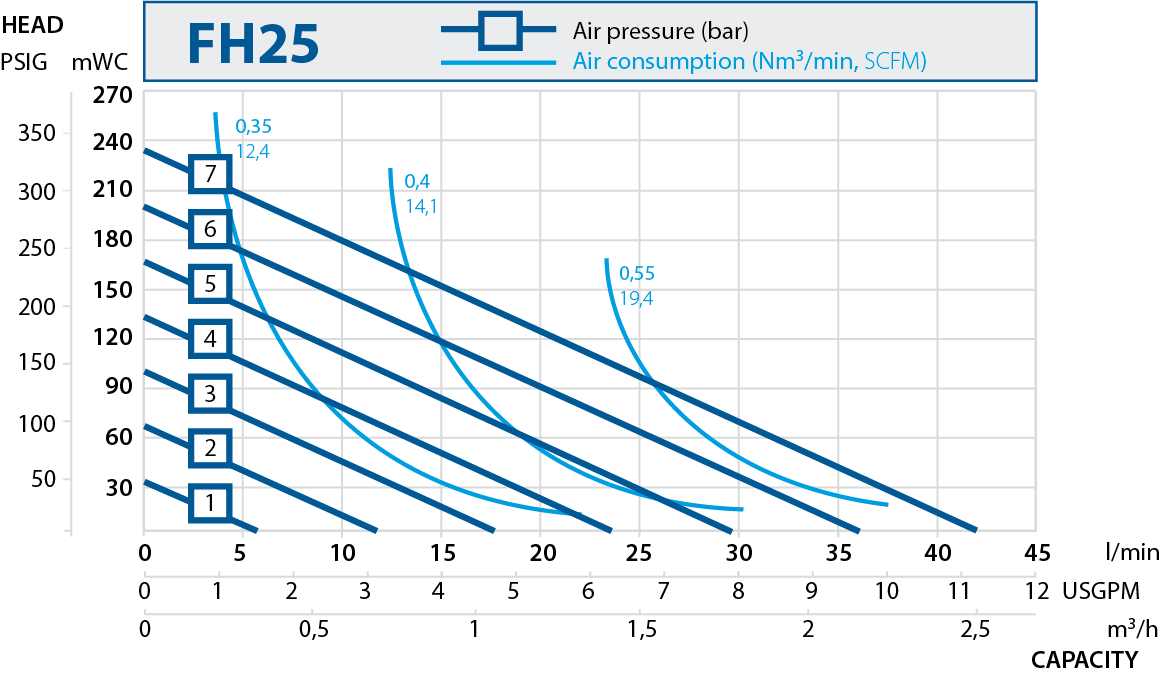

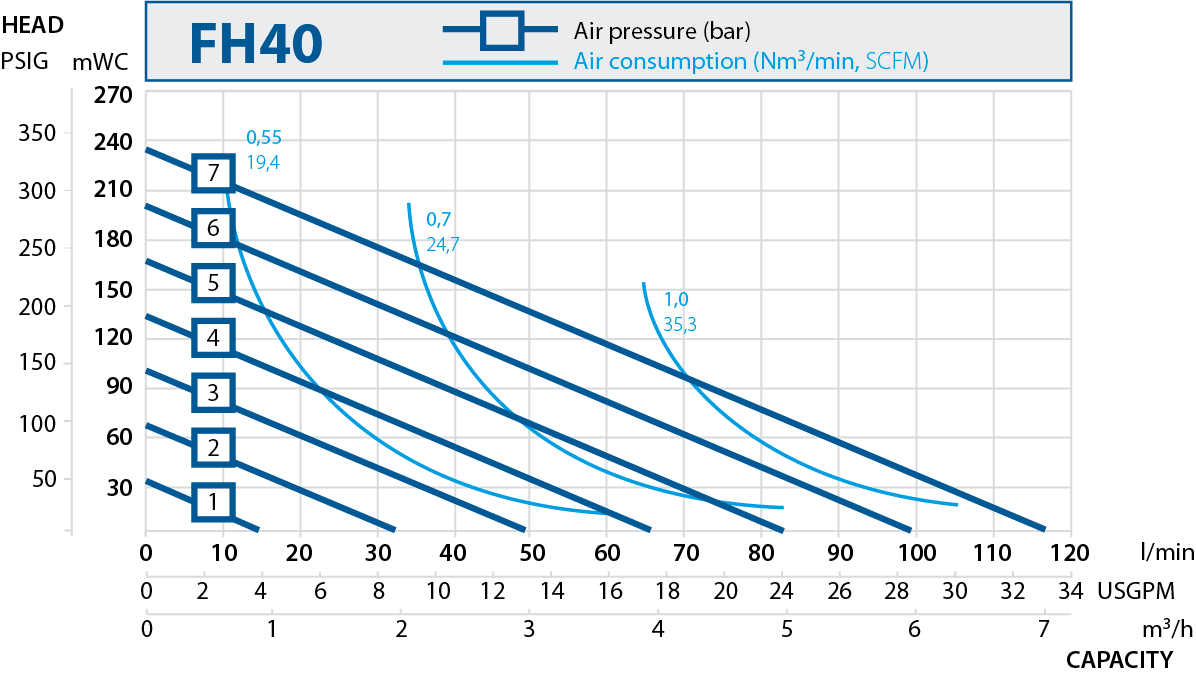

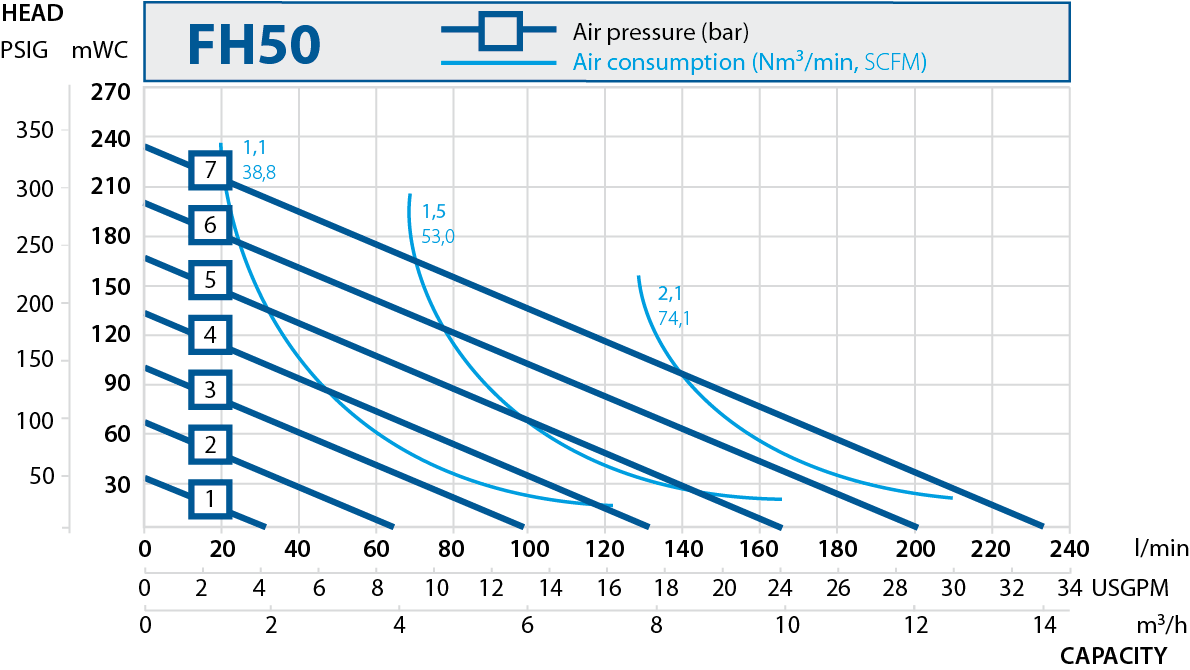

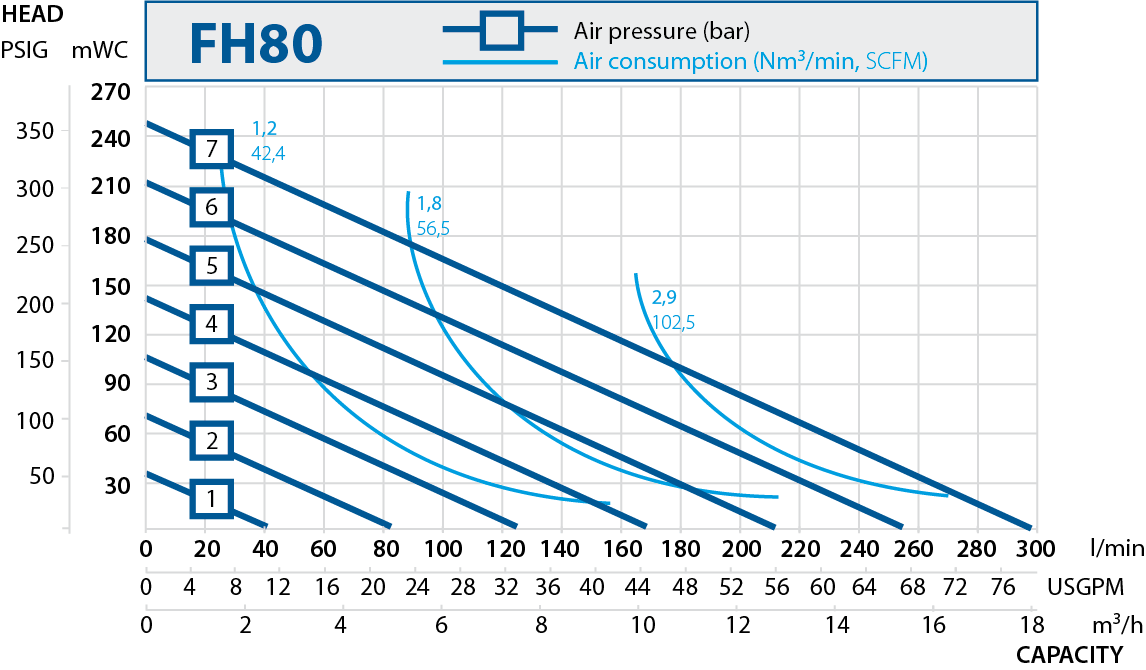

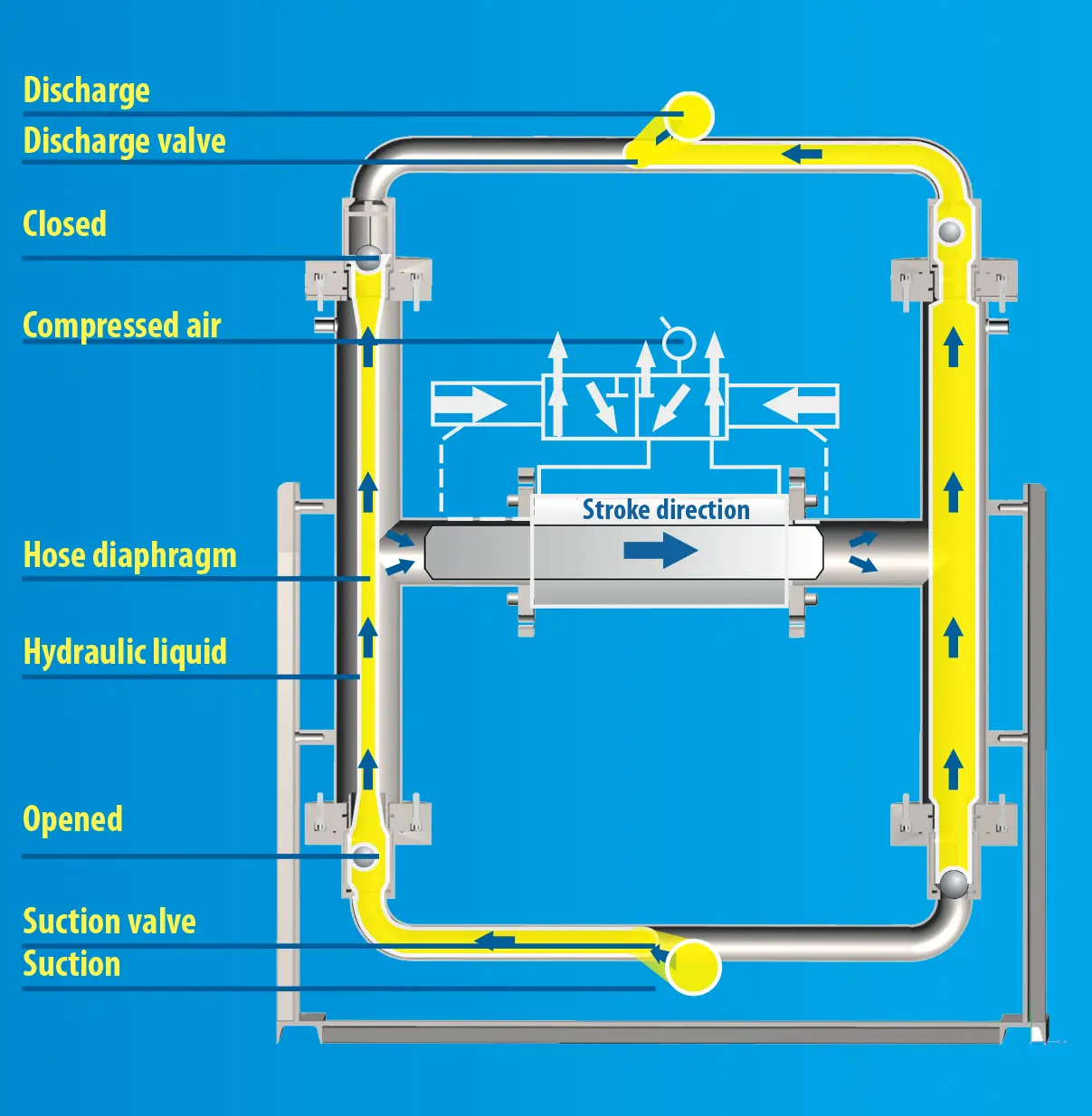

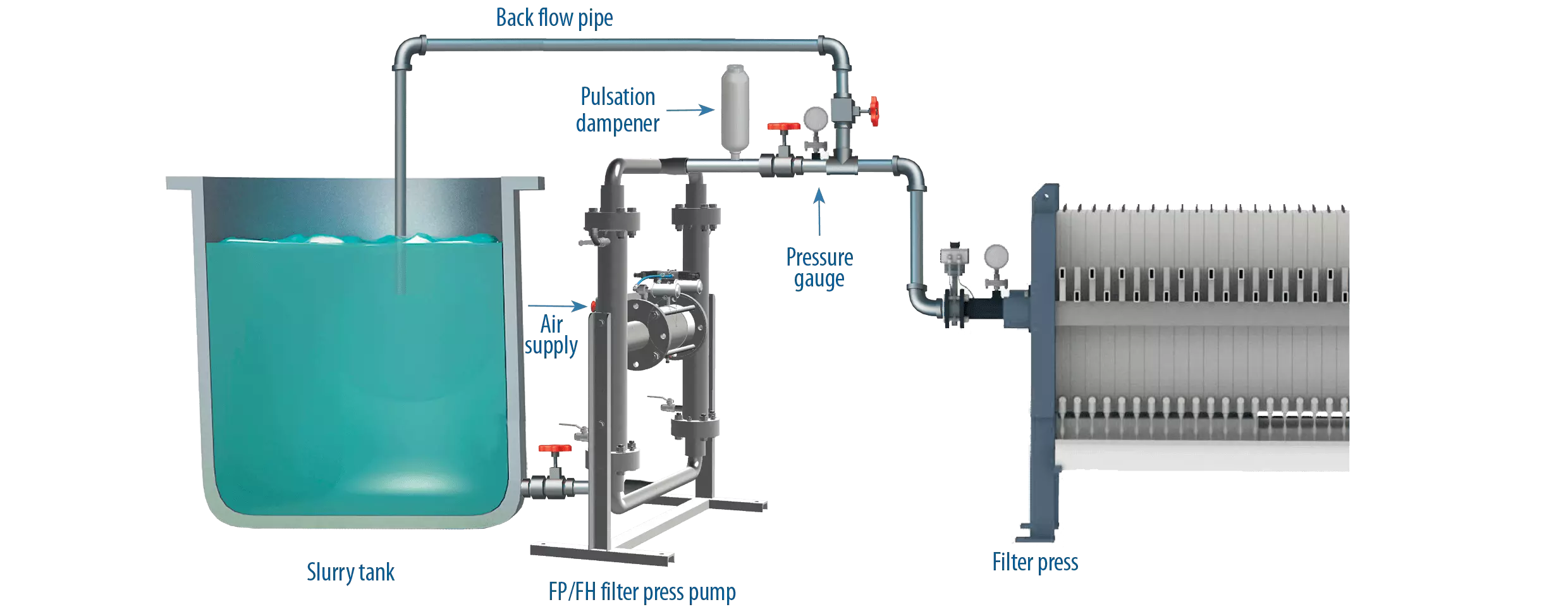

The STEINLE pump is a single or double acting piston diaphragm pump with a hose as the diaphragm. The liquid transferred to the filter press requires exceptionally high performance pumps. They have to supply large quantities of liquid into the empty press as well as small quantities at high pressure when the filter press is filled. This pressure must be maintained for a long period of time.

The pumps are available in FP & FH series with different pressure transmission:

- FP - 1 : 2.4

- FH - 1 : 3.3

Features & benefits

![]() Self-regulating for filter press applications

Self-regulating for filter press applications

By using compressed air to operate the pump, the pump follows the filtration curve automatically. There is no need for speed reduction of electric motors.

![]() High pressure transmission up to 1 : 3.3

High pressure transmission up to 1 : 3.3

By using different sizes of pneumatic pistons the pumps reach 24 bar in the filter press, even with low pressure of compessed air.

![]() Low air consumption

Low air consumption

Due to the piston and cylinder construction with very small dead volumes the compressed air is used very efficiently. Ther is almost no air consumption in the high pressure operation.

![]() Lifetime

Lifetime

Low velocity of the slurries around the valve balls reduce wear in this area.

![]() Dry running capability

Dry running capability

Sealless design and no rotating parts the pump can run dry for a long time without being damaged.

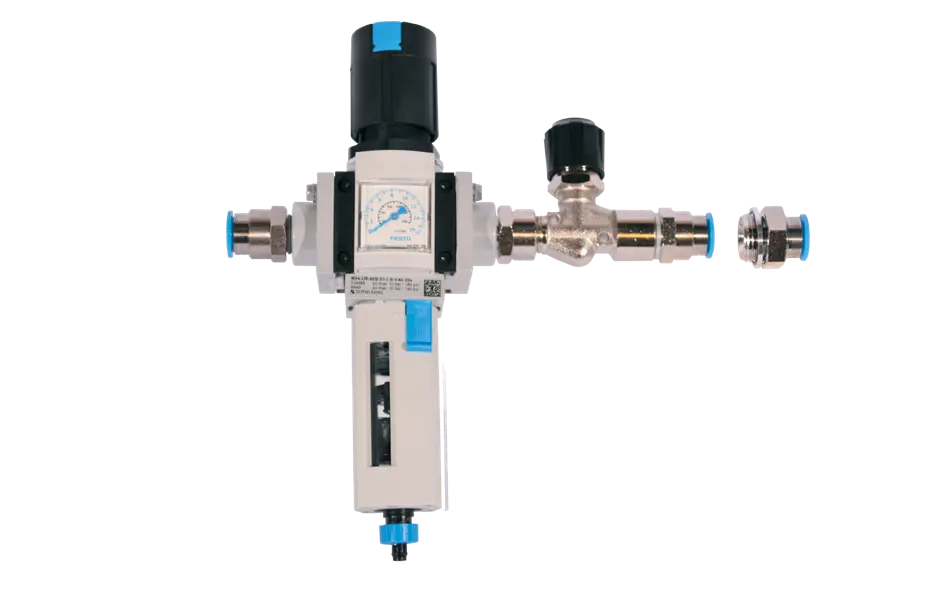

![]() External electronic air valve

External electronic air valve

The electronic control of the external air valve guarantees a safe operation without dead point of the air valve.

![]() Long life time of diaphragms

Long life time of diaphragms

By using tubular diaphragms which are not pressure balanced the stress is reduced to minimum.

![]() Solid construction for heavy duties

Solid construction for heavy duties

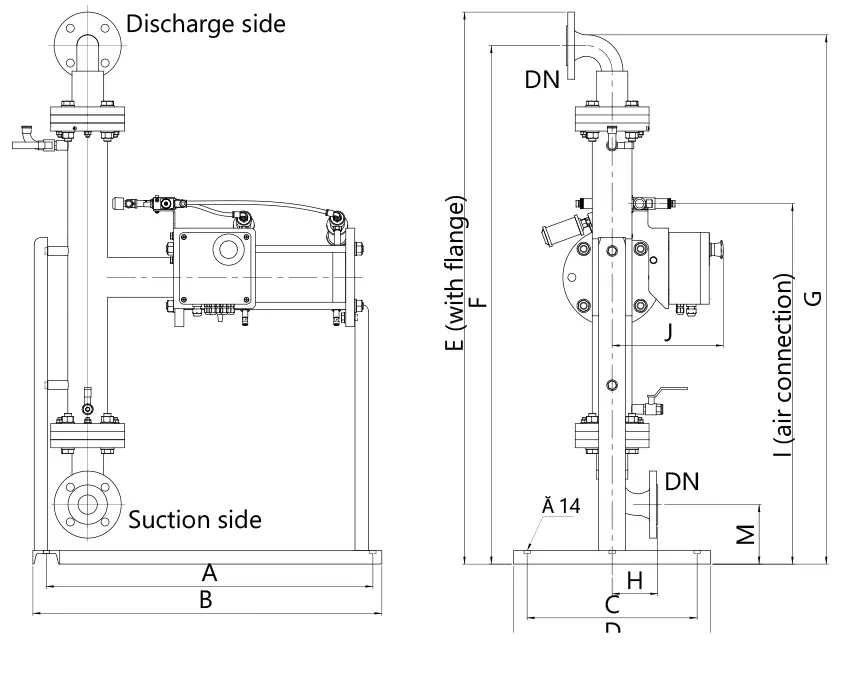

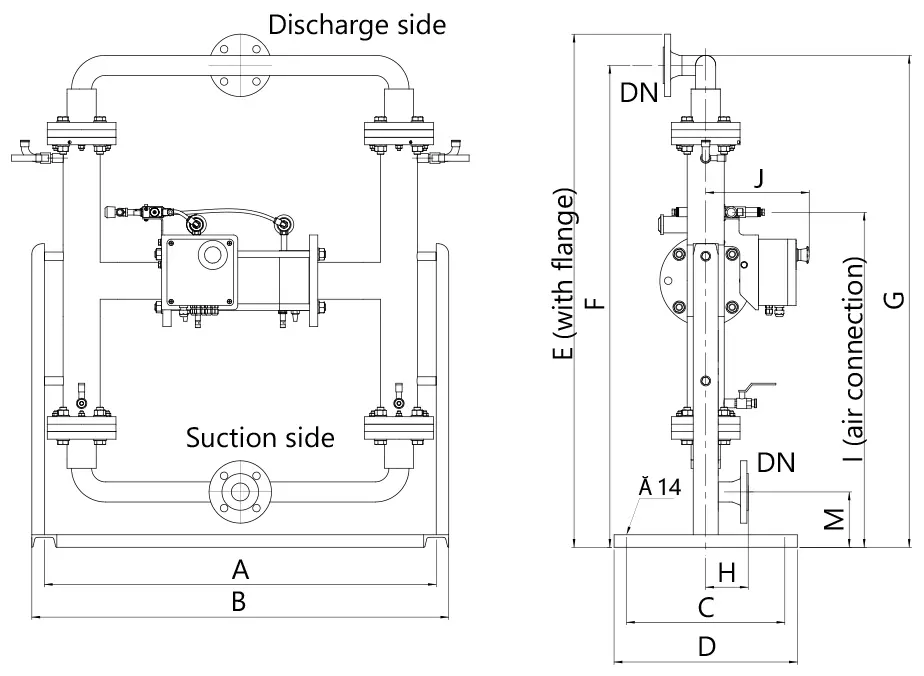

The pump has a flanged construction. No clamps, robust design.

Wide range of applications

Automotive Industry

Filter Press Applications

Chemical and Paper Industry